Interval Packaging

Save time with our scan and pack system which ensures packing accuracy with fixed number of SKUs packed together, giving the right number of units of shipping carton to the customer.

How it works?

Every

item

is

scanned

by

a

barcode

scanner

before

being

packed.

If

any

barcode

can’t

be

read

by

a

scanner,

the

system

will

put

it

away,

marking

it

misfit

to

be

packed.

For

example,

if

the

decided

quantity

for

a

carton

is

20

pieces

solid

SKU.

The

scan

and

pack

system

will

be

configured

to

pack

a

carton

immediately

after

the

scanning

of

20

pcs.

After

completion

of

a

carton,

a

shipping

label

will

be

generated

and

the

scanner

count

will

automatically

reset

to

zero.

In

this

way,

there

is

no

need

to

monitor

the

system

to

keep

the

right

amount

of

SKUs

in

any

carton,

thus,

saving

time.

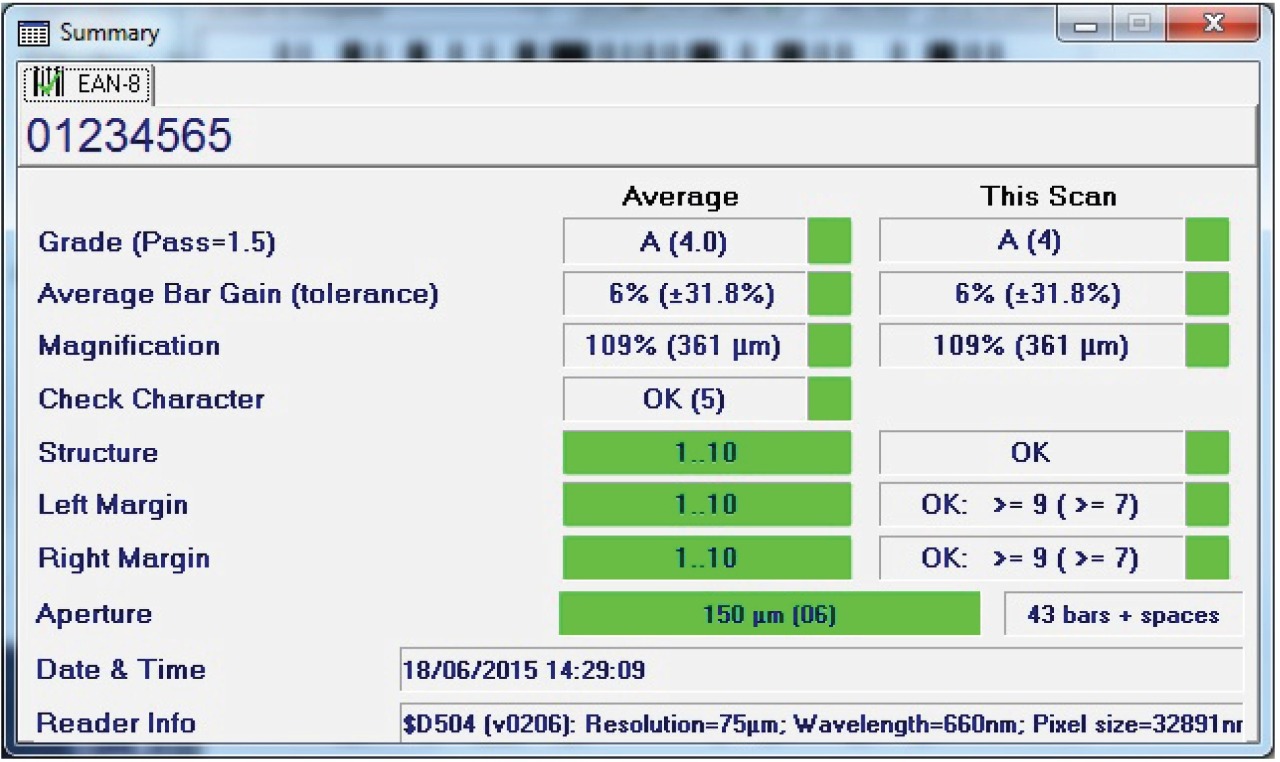

Code Grading

Putting a verification process in place is essential when you are responsible for delivering readable, in-spec barcodes. The true bar code verification process is the only way to ensure that the barcodes function properly.

- Ensures 100% scanability and increases the scanning success rate

- Prevents bad barcodes by recognizing the problem areas before they hamper the distribution channel.

How it works?

Bar code verification system checks quality and scanability by examining the optical characteristics of the code according to industry standards and specifications, based on how actual bar code scanners work.

Material Quality Assurance

Using

Proper

Consumable

is

essential.

Consumable

is

one

of

the

main

part

that

helps

avoid

any

supply

issues

–

and

thus

we

use

proper

consumables

as

per

the

printer.

We

employ

thermal

transfer

printing

which

is

a

high-performance

method

that

ensures

high

durability,

superb

image

resolution

and

longer

print

life

–

everything

your

barcode

needs

and

should

be!

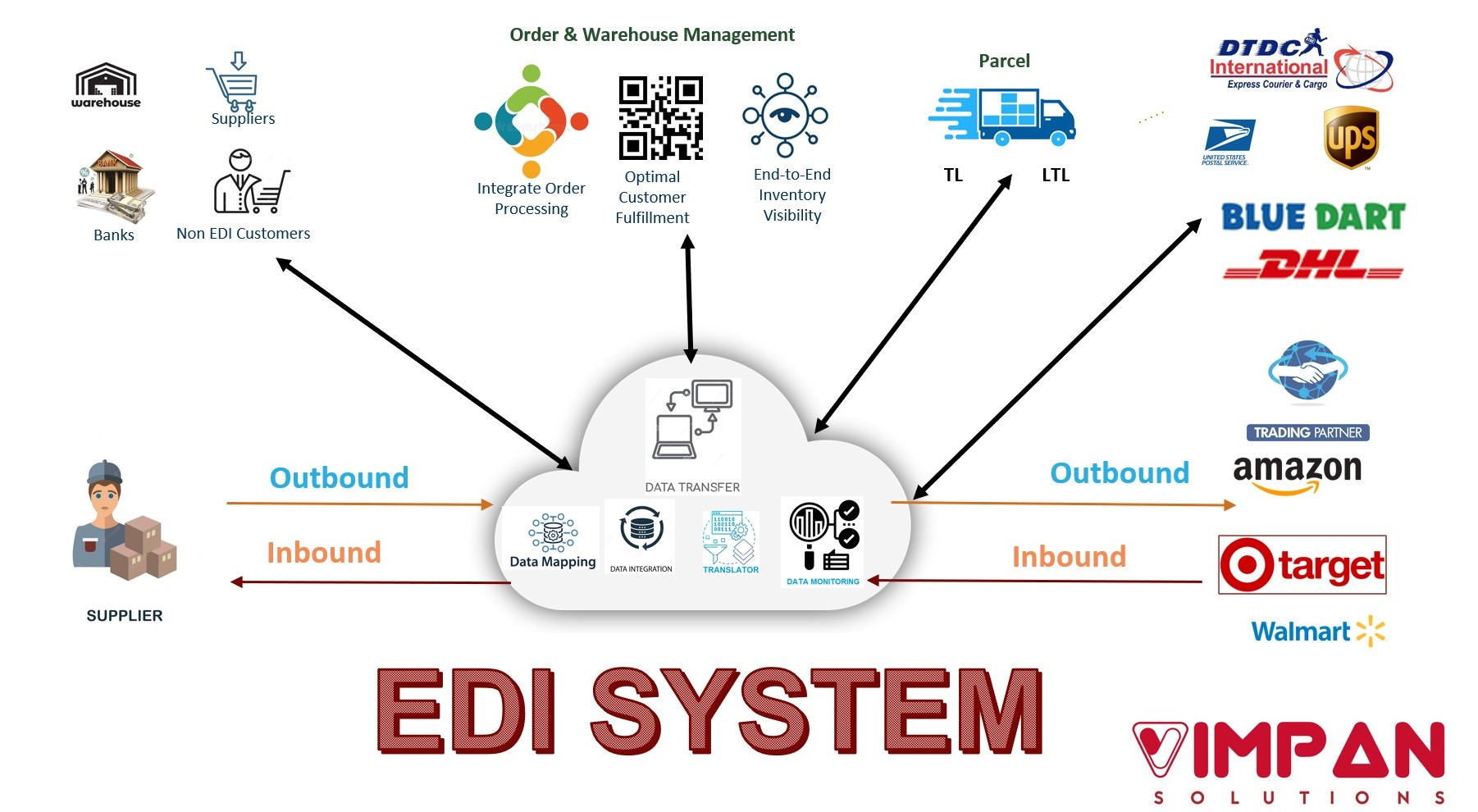

Automated Order Processing (EDI)

Integrating

the

EDI

system

for

important

documentation

is

a

part

of

enhancing

the

supply

chain

agility.

The

system

is

an

interaction

between

the

buyer

and

the

seller

where

the

buyer

generates

a

purchase

order

for

the

seller

and

the

seller

generates

a

final

invoice

for

the

buyer.

How it works?

- Buyer chooses to buy the product

- Using the automated EDI system installed at the buyers’ end, an EDI version of the purchase order is generated – clearly highlighting every detail of the order

- Supplier receives the PO and responds back with the acknowledgement to provide a receipt for the order

Processing orders via EDI systems is less cumbersome, quicker and more accurate.

In-house Solutions

DIY solutions are ideal for clients with experience and expertise at managing barcodes at their end – and we make it easier by providing a range of printers and label consumables (materials and adhesives)

| Printers | Label Consumables |

|---|---|

| • XLP-60X | • Labels for Manufacturing |

| • XLP-51X | • Labels for Distribution and Logistics |

| • XLP-51X-TCS | • Labels for Retailing |

| • Labels for Healthcare and Pharmaceutical | |

| • Labels for Security |